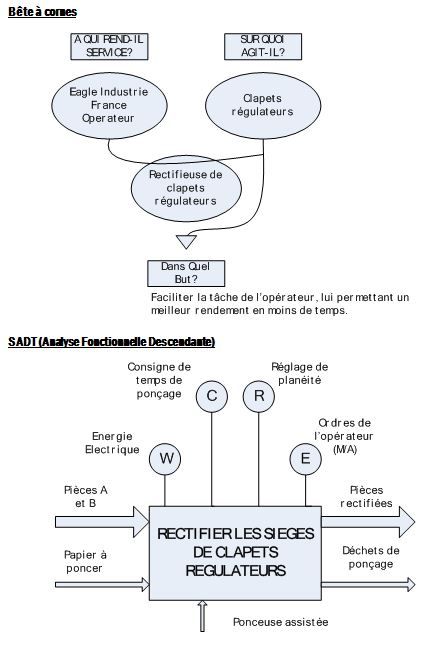

Epicyclic Valve Rectifier

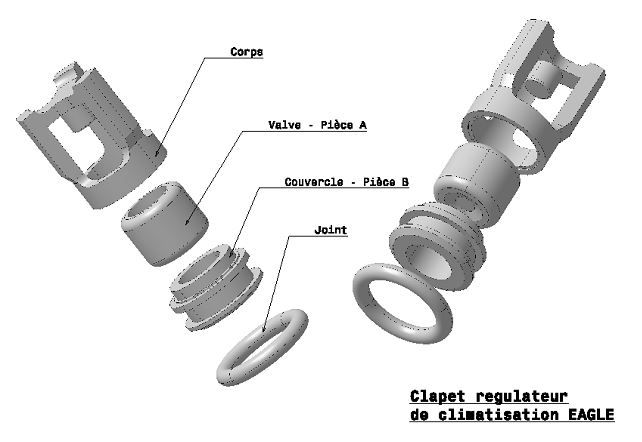

This project was a part of my product design study assignment and was completed for Eagle France, now EKK, on their truck AC valve product.

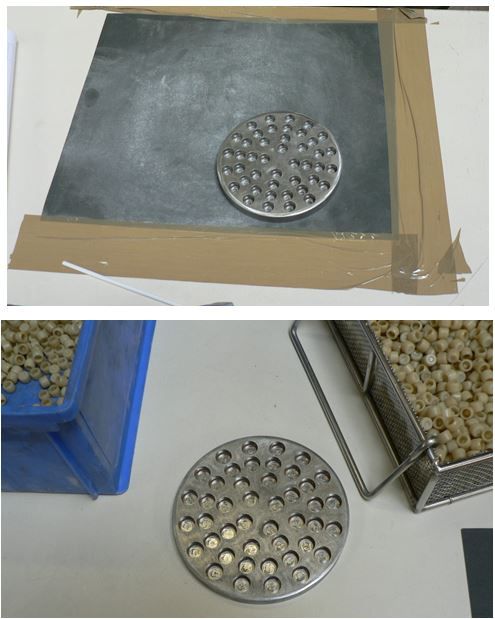

The issue concerned an abnormal defect rate on the rectifying process. The valves were plastic injected then rectified by hand, with an operator manually loading the parts onto a plate and sanding it on a sheet of sandpaper.

The defect rate was over 20% and something needed to be done about that.

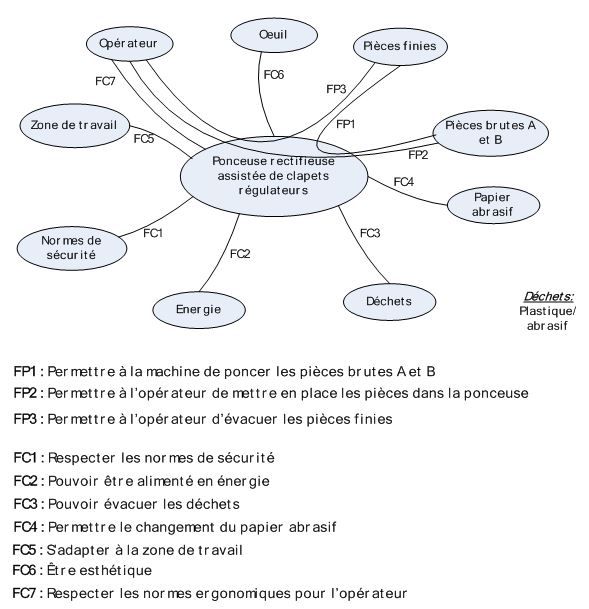

The task was:

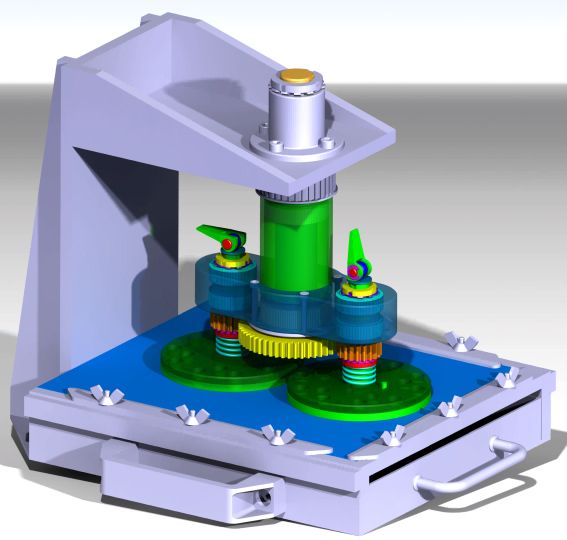

Create a more repeatable, semi-automated solution

Reproduce the manual sanding motion

Keep at least the same cycle time and capacity

Unique solution:

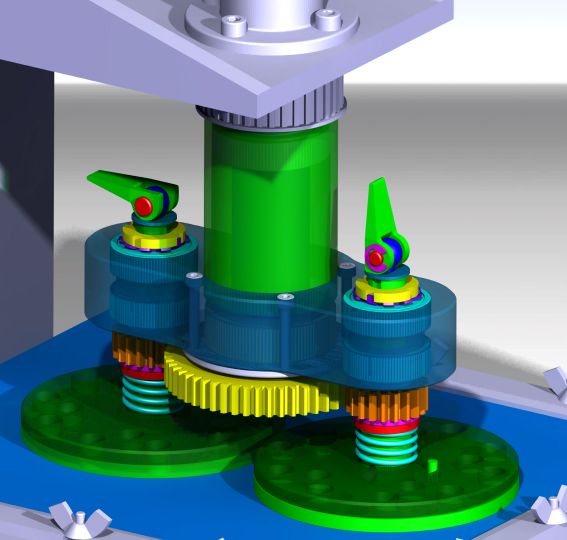

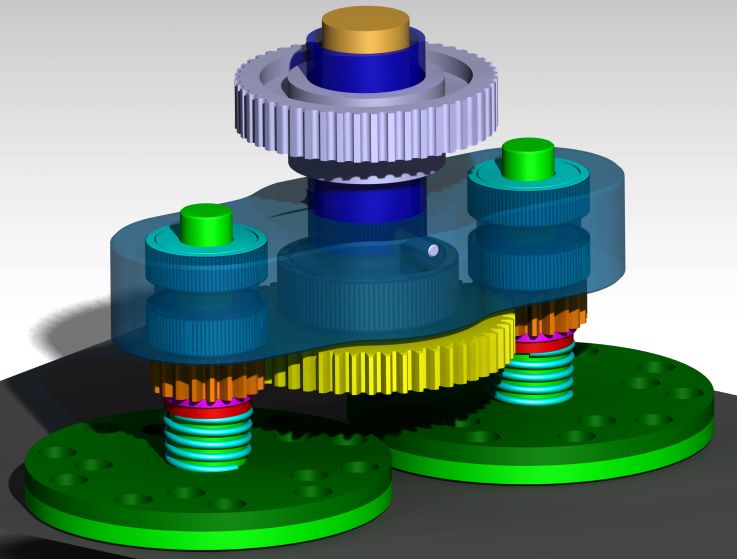

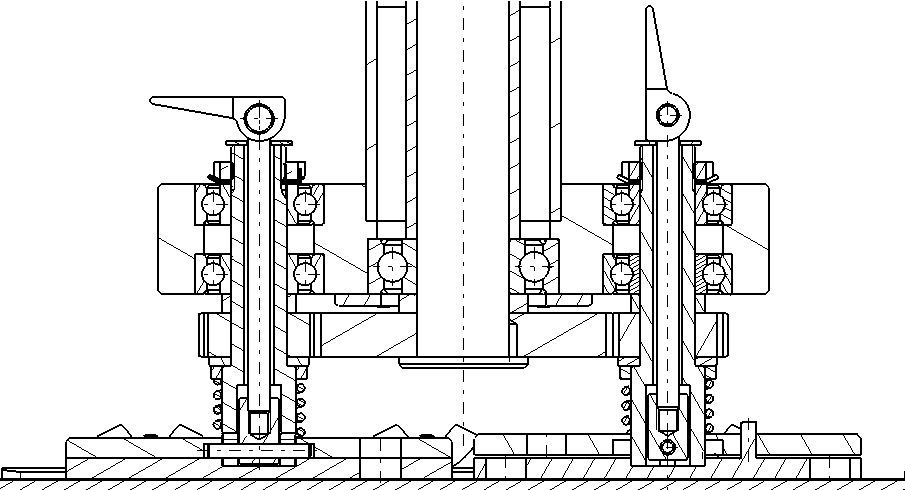

After extensive product analysis and research we chose to go for an epicyclic carrier, offering the most regular sanding action, guaranteeing the best results.

2 support plates drilled with holes to hold the valves radially would then be pressured against the sanding surface with spring loaded pressure plates. The spring load was calculated to reproduce the manual pressure.

The gearing ratio was also calculated based on the manual action, from the individual valve translation speed to the electric motor, passing by the main and planetary axles rotational speed.

On the manufacturing side, the gears, nuts and bearings were chosen from standard catalogs.